Jack stand mounting points

#46

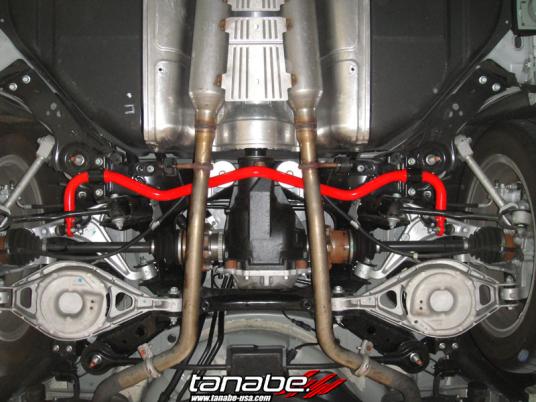

And FWIW the center raised circle on the engine cradle is the jack point for the front, explained earlier in thread but pics always help

#49

Registered User

Either way, you're going to have to put a little DIY into it...how much DIY will depend on your skillset and access to tools and materials.

As mentioned above, you can cram some rags or rubber in there to help take pressure off the pinch weld.

I hope to have my stands by Thursday (weather permitting) and I'll refrain from modifying my hockey pucks until I get them. I'm not sure if I want to cut a groove in the puck, or cut it in half and fasten each half to something else before placing it on the stand.

Last edited by G37Xtreme; 02-25-2015 at 08:42 AM.

#50

Registered User

Perhaps you haven't been reading my posts in this thread. There is a way, but it's going to cost you. You either have to be innovative and industrious...and make a bracket for your existing jack stands, or you have to buy some jack stands with a flat top, and modify a hockey puck, or other material to accommodate the pinch weld.

Either way, you're going to have to put a little DIY into it...how much DIY will depend on your skillset and access to tools and materials.

As mentioned above, you can cram some rags or rubber in there to help take pressure off the pinch weld.

I hope to have my stands by Thursday (weather permitting) and I'll refrain from modifying my hockey pucks until I get them. I'm not sure if I want to cut a groove in the puck, or cut it in half and fasten each half to something else before placing it on the stand.

Either way, you're going to have to put a little DIY into it...how much DIY will depend on your skillset and access to tools and materials.

As mentioned above, you can cram some rags or rubber in there to help take pressure off the pinch weld.

I hope to have my stands by Thursday (weather permitting) and I'll refrain from modifying my hockey pucks until I get them. I'm not sure if I want to cut a groove in the puck, or cut it in half and fasten each half to something else before placing it on the stand.

Ill just have to be careful and a bit creative.

thanks =]

#52

The correct way to do it is either jack the front at the engine cradle center point, the rear at the differential, or each side scissor jack point (straddling the indented pinch weld). How you accomplish that is up to you.

There are a few safe jack stand points, I mentioned one of them in my reply a few posts up, using the unibody frame rails isn't something I'd recommend but that's me.

There are a few safe jack stand points, I mentioned one of them in my reply a few posts up, using the unibody frame rails isn't something I'd recommend but that's me.

#53

I ran into the same issue for the jackstands. I'm almost 90% sure I'll be buying two pairs of the Jackpoint Jackstands. Yes it's pricey, but to just use a jack, lift up the car and then drop it down on to a jackstand is awesome! What I did when I was powder coating my calipers, I jacked up the car and then placed the jackstands parallel with the pinch weld but behind it. Wished I took pictures to show you what I mean. The jackstand I was using at the time was the Torin jackstand and I purchased rubber cover for it. It worked out well nothing got damaged. Lets see if I can use text to give you a better understanding.

Jackstand --->||<----pinch weld.

Rather than + (the "-" being the jack stand and the "|" being the pinch weld. Hope that helps.

Jackstand --->||<----pinch weld.

Rather than + (the "-" being the jack stand and the "|" being the pinch weld. Hope that helps.

#55

Registered User

They are much larger than I expected. When shown next to a normal jack stand, you begin to realize how freakishly huge they are.

#57

Registered User

I got my Esco jack stands today. They dwarf my Torin double locking stands.

The rubber top also comes off leaving a half inch hole which I'll use to help secure the puck in place. I may even write a diy on the modification once I decide how I'll do it.

I've already cut a groove into a hockey puck for use on my jack. As you can see, the puck nestles on the stand pretty well, but if it was larger, it would be perfect. I may be cutting the puck in half instead and mounting the halves on a round plate that fits exactly into the circle cradle. Ultimately, a half inch bolt will extend into that hole to keep everything stable, but I can't secure it with a nut (well I may be able to, but that would complicate things in other ways)

The rubber top also comes off leaving a half inch hole which I'll use to help secure the puck in place. I may even write a diy on the modification once I decide how I'll do it.

I've already cut a groove into a hockey puck for use on my jack. As you can see, the puck nestles on the stand pretty well, but if it was larger, it would be perfect. I may be cutting the puck in half instead and mounting the halves on a round plate that fits exactly into the circle cradle. Ultimately, a half inch bolt will extend into that hole to keep everything stable, but I can't secure it with a nut (well I may be able to, but that would complicate things in other ways)

#59

Maybe we should start a new thread "show us your pinch welds" and see just how bad some of ours have held up. Mine aren't pristine but for all the lifting I've done they look OK. The first is the drivers side, guess I'd better look at that bolt that seems to be quite bent  followed by drivers rear, pass rear, pass front.

followed by drivers rear, pass rear, pass front.

#60

Registered User

I've been racking my brain on this modification. I was up until 3am last night working things out.

I'm still not sure if I want to attach the hockey puck to the stand, or let it just sit there. I'm also not sure if I want to use the hole in the stand (not to mount, just to center and stabilize) the puck.

One of my ideas is to drill a hole on one half, glue in a magnet, and attach the puck to the car. Then, I'd lower the car and puck onto the stand.

I can either cut a groove in the puck, or cut it in half and attach a bracket to keep the halves properly spaced. I can even cut a groove and attach a bracket as seen below.

Everything is still up in the air (actually, until I figure this out, nothing is in the air )

)

The good news it's, I've got 6 more hockey pucks being delivered today (I love you Amazon prime) so I've got 10 fresh, unaltered pucks to work with.

I may make two styles, we'll see.

I'm still not sure if I want to attach the hockey puck to the stand, or let it just sit there. I'm also not sure if I want to use the hole in the stand (not to mount, just to center and stabilize) the puck.

One of my ideas is to drill a hole on one half, glue in a magnet, and attach the puck to the car. Then, I'd lower the car and puck onto the stand.

I can either cut a groove in the puck, or cut it in half and attach a bracket to keep the halves properly spaced. I can even cut a groove and attach a bracket as seen below.

Everything is still up in the air (actually, until I figure this out, nothing is in the air

)

)The good news it's, I've got 6 more hockey pucks being delivered today (I love you Amazon prime) so I've got 10 fresh, unaltered pucks to work with.

I may make two styles, we'll see.