Scientific Papers on DLC! No more guessing about what oil to use!

#1

Scientific Papers on DLC! No more guessing about what oil to use!

Hello all,

I found some great papers on DLC, some even published by nissan scientists! I got access to the databases where the papers were stored and I shall be posting the PDFs here. See some initial papers attached.

I only read a part of one of them so far, but the results are very interesting. Please feel free to use this thread to share your thoughts on the subject.

Super low friction of DLC applied to engine cam follower lubricated

with ester-containing oil

Improvement of boundary lubrication properties of diamond-like

carbon (DLC) films due to metal addition

Boundary lubrication mechanisms of carbon coatings by MoDTC

and ZDDP additives

I found some great papers on DLC, some even published by nissan scientists! I got access to the databases where the papers were stored and I shall be posting the PDFs here. See some initial papers attached.

I only read a part of one of them so far, but the results are very interesting. Please feel free to use this thread to share your thoughts on the subject.

Abstract

This paper presents a material combination that reduces the friction coefficient markedly to a superlow friction regime (below 0.01)

under boundary lubrication. A state approaching superlubricity was obtained by sliding hardened steel pins on a hydrogen-free

diamond-like carbon (DLC) film (ta-C) lubricated with a poly-alpha-olefin (PAO) oil containing 1 mass% of an ester additive. This ta-C/

steel material combination showed a superlow friction coefficient of 0.006 at a sliding speed of 0.1 m/s. A hydrogencontaining DLC

coating/steel combination also showed a lower friction coefficient in air than a steel/steel combination, 0.1 vs. 0.8, but no large reduction

was observed when the sliding surfaces were lubricated with ordinary 5W-30 engine oil and the PAO oil containing an ester additive. The

friction coefficient of the hydrogen containing DLC/steel combination lubricated with the PAO containing an ester additive was above

0.05. On the other hand, the superlow friction performance demonstrates that the rolling contact friction level of needle roller bearings

can be obtained in sliding contact under a boundary lubrication condition. It is planned to apply this advanced DLC coating technology

to valve lifters lubricated with a newly formulated engine oil in actual mass-produced gasoline engines. A larger friction reduction of

more than 45% is expected to be obtained at an engine speed of 2000 rpm.

This paper presents a material combination that reduces the friction coefficient markedly to a superlow friction regime (below 0.01)

under boundary lubrication. A state approaching superlubricity was obtained by sliding hardened steel pins on a hydrogen-free

diamond-like carbon (DLC) film (ta-C) lubricated with a poly-alpha-olefin (PAO) oil containing 1 mass% of an ester additive. This ta-C/

steel material combination showed a superlow friction coefficient of 0.006 at a sliding speed of 0.1 m/s. A hydrogencontaining DLC

coating/steel combination also showed a lower friction coefficient in air than a steel/steel combination, 0.1 vs. 0.8, but no large reduction

was observed when the sliding surfaces were lubricated with ordinary 5W-30 engine oil and the PAO oil containing an ester additive. The

friction coefficient of the hydrogen containing DLC/steel combination lubricated with the PAO containing an ester additive was above

0.05. On the other hand, the superlow friction performance demonstrates that the rolling contact friction level of needle roller bearings

can be obtained in sliding contact under a boundary lubrication condition. It is planned to apply this advanced DLC coating technology

to valve lifters lubricated with a newly formulated engine oil in actual mass-produced gasoline engines. A larger friction reduction of

more than 45% is expected to be obtained at an engine speed of 2000 rpm.

with ester-containing oil

Abstract

The effects of added materials such as metals like titanium (Ti), molybdenum (Mo) and iron (Fe) diamond-like carbon (DLC)

films on boundary lubrication and microtribological properties were investigated. The nanoindentation hardness and microwear

resistance can be improved by adding the proper metal to DLC films, as evaluated by atomic force microscopy (AFM). Boundary

lubrication properties of DLC films with metals are improved as comparing with DLC films without metal under lubricant with

both MoDTC and ZDDP additives. Moreover, lower friction coefficient of l ¼ 0:03 than carburized steel is exhibited with the

appropriate quantity of Ti added. The tribochemical reactant was formed on the sliding surface of the Ti-containing DLC film

like as carburized steel. Higher mechanical damping materials containing elements, such as Mo, Zn, P and S, formed tribochemical

reactors as observed by X-ray photoemission spectroscopy (XPS) and AFM force modulation methods.

The effects of added materials such as metals like titanium (Ti), molybdenum (Mo) and iron (Fe) diamond-like carbon (DLC)

films on boundary lubrication and microtribological properties were investigated. The nanoindentation hardness and microwear

resistance can be improved by adding the proper metal to DLC films, as evaluated by atomic force microscopy (AFM). Boundary

lubrication properties of DLC films with metals are improved as comparing with DLC films without metal under lubricant with

both MoDTC and ZDDP additives. Moreover, lower friction coefficient of l ¼ 0:03 than carburized steel is exhibited with the

appropriate quantity of Ti added. The tribochemical reactant was formed on the sliding surface of the Ti-containing DLC film

like as carburized steel. Higher mechanical damping materials containing elements, such as Mo, Zn, P and S, formed tribochemical

reactors as observed by X-ray photoemission spectroscopy (XPS) and AFM force modulation methods.

carbon (DLC) films due to metal addition

Abstract

Fuel economy and reduction of harmful elements in lubricants are becoming important issues in the automotive industry. An approach to

respond to these requirements is the potential use of low friction coatings in engine components exposed to boundary lubrication conditions.

Diamond-like-carbon (DLC) coatings present a wide range of tribological behavior, including friction coefficients in ultra-high vacuum

below 0.02. The engine oil environment which provides similar favourable air free conditions might lead to such low friction levels.

In this work, the friction and wear properties of DLC coatings in boundary lubrication conditions have been investigated as a function of

the hydrogen content in the carbon coating. Their interaction with ZDDP which is the exclusive antiwear agent in most automotive

lubrication blends and friction-modifier additive MoDTC has been studied. Hydrogenated DLC coatings can be better lubricated in the

presence of the friction-modifier additive MoDTC through the formation of MoS2 solid lubricant material than can non-hydrogenated DLC.

In contrast, the antiwear additive ZDDP does not significantly affect the wear behavior of DLC coatings. The good tribological performances

of the DLC coatings suggest that they can contribute to reduce friction and wear in the engine, and so permit the significant decrease of

additive concentration.

Fuel economy and reduction of harmful elements in lubricants are becoming important issues in the automotive industry. An approach to

respond to these requirements is the potential use of low friction coatings in engine components exposed to boundary lubrication conditions.

Diamond-like-carbon (DLC) coatings present a wide range of tribological behavior, including friction coefficients in ultra-high vacuum

below 0.02. The engine oil environment which provides similar favourable air free conditions might lead to such low friction levels.

In this work, the friction and wear properties of DLC coatings in boundary lubrication conditions have been investigated as a function of

the hydrogen content in the carbon coating. Their interaction with ZDDP which is the exclusive antiwear agent in most automotive

lubrication blends and friction-modifier additive MoDTC has been studied. Hydrogenated DLC coatings can be better lubricated in the

presence of the friction-modifier additive MoDTC through the formation of MoS2 solid lubricant material than can non-hydrogenated DLC.

In contrast, the antiwear additive ZDDP does not significantly affect the wear behavior of DLC coatings. The good tribological performances

of the DLC coatings suggest that they can contribute to reduce friction and wear in the engine, and so permit the significant decrease of

additive concentration.

and ZDDP additives

Last edited by bythabay; 12-04-2010 at 05:17 AM.

#4

I know it's a lot to swallow, but the answer lies in the documents and some oil analysis reports.

After taking a very brief looks at the papers and reviewing several used oil analysis reports, I believe I have confirmed the following information as fact:

1) PAO ester is recommended by Nissan to lubricate the drivetrain (duh!)

2) The secret solid ingredient in Nissan Ester Oil isn't a diamond-like compound, but instead, it is good-ol' Molybdenum!

3) When used with the proper amount of ZDDP, Moly becomes most effective at reducing the co-efficient of friction.

4) Nissan's oil, according to oil reports, is full of Moly and ZDDP. It has an additive package similar to that of the highest quality Synthetics.

For example, some Mobil1 oils contain on average about 70 ppm of Moly, while Amsoil Signature Series typically contains almost zero Moly, but is very heavily fortified with ZDDP. Combining the two seemed to provide the best test results when used with the Hydrogen-Free DLC coating.

So far, my conclusion is that Nissan's base stock oil sucks and that if they had chosen a good quality ester oil as their base stock instead, their oil would hold up much better. The reason their oil is so expensive, is partly because of how much Moly and ZDDP is in it.. Or perhaps it's just Moly, and I am reading the reports wrong.

So.... what oil should you use? I think what I am going to do, is combine Amsoil Signature Series with a Moly additive.

After taking a very brief looks at the papers and reviewing several used oil analysis reports, I believe I have confirmed the following information as fact:

1) PAO ester is recommended by Nissan to lubricate the drivetrain (duh!)

2) The secret solid ingredient in Nissan Ester Oil isn't a diamond-like compound, but instead, it is good-ol' Molybdenum!

3) When used with the proper amount of ZDDP, Moly becomes most effective at reducing the co-efficient of friction.

4) Nissan's oil, according to oil reports, is full of Moly and ZDDP. It has an additive package similar to that of the highest quality Synthetics.

For example, some Mobil1 oils contain on average about 70 ppm of Moly, while Amsoil Signature Series typically contains almost zero Moly, but is very heavily fortified with ZDDP. Combining the two seemed to provide the best test results when used with the Hydrogen-Free DLC coating.

So far, my conclusion is that Nissan's base stock oil sucks and that if they had chosen a good quality ester oil as their base stock instead, their oil would hold up much better. The reason their oil is so expensive, is partly because of how much Moly and ZDDP is in it.. Or perhaps it's just Moly, and I am reading the reports wrong.

So.... what oil should you use? I think what I am going to do, is combine Amsoil Signature Series with a Moly additive.

Last edited by bythabay; 12-04-2010 at 11:26 AM.

#5

Here are some conclusion sections from the papers:

MoDTC = Molybdenum

MoS2 = Molybedenum

a-C = Hydrogen-Free DLC

MoDTC = Molybdenum

MoS2 = Molybedenum

a-C = Hydrogen-Free DLC

Boundary lubrication properties of lubricant with

MoDTC and microtribological properties of metalcontaining

DLC and DLC without metal films have

been evaluated. The main results are as follows:

1. Boundary lubrication properties of DLC films can

be improved due to addition of metals such as Ti,

Mo and Fe. Especially, Ti-containing DLC films

showed the lowest friction coefficient of l ¼ 0:03 in

MoDTC-containing lubricant in spite of the high

friction coefficient of DLC without metal.

2. A tribochemical reactor containing elements, such as

Mo, Zn and S, were formed on sliding tracks on Ticontaining

DLC films like as carburized Cr–Mo

steel, as revealed by evaluations by XPS and the

AFM force modulation method.

3. Viscoelastic properties such as high damping and

tan d of sliding tracks on the Ti-containing DLC

film that showed a low friction coefficient, became

high compared with those of the no-sliding area.

Therefore, on the sliding surface, lower shearing

resistant reactants were formed.

4. Nanoindentation hardness and microwear resistance

can be improved by the addition of titanium and

molybdenum to DLC films

5. Friction and wear can be reduced by the addition of

Ti into DLC films in a dry environment.

MoDTC and microtribological properties of metalcontaining

DLC and DLC without metal films have

been evaluated. The main results are as follows:

1. Boundary lubrication properties of DLC films can

be improved due to addition of metals such as Ti,

Mo and Fe. Especially, Ti-containing DLC films

showed the lowest friction coefficient of l ¼ 0:03 in

MoDTC-containing lubricant in spite of the high

friction coefficient of DLC without metal.

2. A tribochemical reactor containing elements, such as

Mo, Zn and S, were formed on sliding tracks on Ticontaining

DLC films like as carburized Cr–Mo

steel, as revealed by evaluations by XPS and the

AFM force modulation method.

3. Viscoelastic properties such as high damping and

tan d of sliding tracks on the Ti-containing DLC

film that showed a low friction coefficient, became

high compared with those of the no-sliding area.

Therefore, on the sliding surface, lower shearing

resistant reactants were formed.

4. Nanoindentation hardness and microwear resistance

can be improved by the addition of titanium and

molybdenum to DLC films

5. Friction and wear can be reduced by the addition of

Ti into DLC films in a dry environment.

The super low friction coefficient of 0.006 was obtained

by the material combination of the steel pin/ta-C disc pair

lubricated with the ester containing PAO oil at the

boundary lubrication condition. This value was comparable

to the friction coefficient of the roller bearing (pure

rolling).

ARTICLE IN PRESS

Fig. 5. Single cam and follower test rig.

Fig. 6. Reduction in cam/follower friction torque.

Fig. 7. Engine valvetrain motoring test.

Fig. 8. Reduction in valvetrain friction torque.

1684 M. Kano / Tribology International 39 (2006) 1682–1685

It is planned to apply this advanced DLC coating

technology to valve lifters lubricated with a newly

formulated ester containing engine oil in actual massproduced

gasoline engines. A larger friction reduction of

more than 45% is expected to be obtained at an engine

speed of 2000 rpm by using the ester containing oil.

by the material combination of the steel pin/ta-C disc pair

lubricated with the ester containing PAO oil at the

boundary lubrication condition. This value was comparable

to the friction coefficient of the roller bearing (pure

rolling).

ARTICLE IN PRESS

Fig. 5. Single cam and follower test rig.

Fig. 6. Reduction in cam/follower friction torque.

Fig. 7. Engine valvetrain motoring test.

Fig. 8. Reduction in valvetrain friction torque.

1684 M. Kano / Tribology International 39 (2006) 1682–1685

It is planned to apply this advanced DLC coating

technology to valve lifters lubricated with a newly

formulated ester containing engine oil in actual massproduced

gasoline engines. A larger friction reduction of

more than 45% is expected to be obtained at an engine

speed of 2000 rpm by using the ester containing oil.

MoDTC and ZDDP additives react directly on amorphous

carbon surfaces. They seem to be more active with

selected hydrogenated amorphous carbon surfaces. The

friction and wear performances are improved by coating

both counterfaces. XPS analysis show the formation of

MoS2 in the contact area only. The presence of zinc

phosphate has been detected by EDX in the wear debris

collected inside the tribofilm. On amorphous carbon

surfaces, the role of antiwear ZDDP agent seems to be

principally to enhance the formation of MoS2 sheets. The

composition of tribofilm appears similar to that of tribofilm

obtained on steel surfaces in the same lubrication conditions.

It is interesting to notice that tribochemical

reactions can occur without the presence of iron catalyst

element in the tribo-system.

carbon surfaces. They seem to be more active with

selected hydrogenated amorphous carbon surfaces. The

friction and wear performances are improved by coating

both counterfaces. XPS analysis show the formation of

MoS2 in the contact area only. The presence of zinc

phosphate has been detected by EDX in the wear debris

collected inside the tribofilm. On amorphous carbon

surfaces, the role of antiwear ZDDP agent seems to be

principally to enhance the formation of MoS2 sheets. The

composition of tribofilm appears similar to that of tribofilm

obtained on steel surfaces in the same lubrication conditions.

It is interesting to notice that tribochemical

reactions can occur without the presence of iron catalyst

element in the tribo-system.

#6

Good info. Have you posted this on bobistheoilguy.com? If so please give us the link so we can participate in the discussion. Someone on that forum would understand the details.

#8

Registered User

I remember reading that Redline was high in both ZDDP and Moly. Although it costs nearly as much as Nissan Ester oil. But theoretically should be better (less shearing?) than Nissan's if you use it for longer intervals like schedule 2 or somewhere in the middle.

#9

Registered User

Nothing new here, These papers were referenced, reduced to plain languange and

discussed adnauseam in oil threads last year. Few read, fewer understood and most

couldn't comprehend it's all about emerging emissions technology.

discussed adnauseam in oil threads last year. Few read, fewer understood and most

couldn't comprehend it's all about emerging emissions technology.

#11

Registered User

iTrader: (4)

After taking a very brief looks at the papers and reviewing several used oil analysis reports, I believe I have confirmed the following information as fact:

1) PAO ester is recommended by Nissan to lubricate the drivetrain (duh!)

2) The secret solid ingredient in Nissan Ester Oil isn't a diamond-like compound, but instead, it is good-ol' Molybdenum!

3) When used with the proper amount of ZDDP, Moly becomes most effective at reducing the co-efficient of friction.

4) Nissan's oil, according to oil reports, is full of Moly and ZDDP. It has an additive package similar to that of the highest quality Synthetics.

For example, some Mobil1 oils contain on average about 70 ppm of Moly, while Amsoil Signature Series typically contains almost zero Moly, but is very heavily fortified with ZDDP. Combining the two seemed to provide the best test results when used with the Hydrogen-Free DLC coating.

So far, my conclusion is that Nissan's base stock oil sucks and that if they had chosen a good quality ester oil as their base stock instead, their oil would hold up much better. The reason their oil is so expensive, is partly because of how much Moly and ZDDP is in it.. Or perhaps it's just Moly, and I am reading the reports wrong.

So.... what oil should you use? I think what I am going to do, is combine Amsoil Signature Series with a Moly additive.

1) PAO ester is recommended by Nissan to lubricate the drivetrain (duh!)

2) The secret solid ingredient in Nissan Ester Oil isn't a diamond-like compound, but instead, it is good-ol' Molybdenum!

3) When used with the proper amount of ZDDP, Moly becomes most effective at reducing the co-efficient of friction.

4) Nissan's oil, according to oil reports, is full of Moly and ZDDP. It has an additive package similar to that of the highest quality Synthetics.

For example, some Mobil1 oils contain on average about 70 ppm of Moly, while Amsoil Signature Series typically contains almost zero Moly, but is very heavily fortified with ZDDP. Combining the two seemed to provide the best test results when used with the Hydrogen-Free DLC coating.

So far, my conclusion is that Nissan's base stock oil sucks and that if they had chosen a good quality ester oil as their base stock instead, their oil would hold up much better. The reason their oil is so expensive, is partly because of how much Moly and ZDDP is in it.. Or perhaps it's just Moly, and I am reading the reports wrong.

So.... what oil should you use? I think what I am going to do, is combine Amsoil Signature Series with a Moly additive.

Nissan should have just spec'd Redline from the beginning. Redline, Schaeffers, and Motul 300V are the 3 closest IIRC to the Nissan Ester Oil specs.

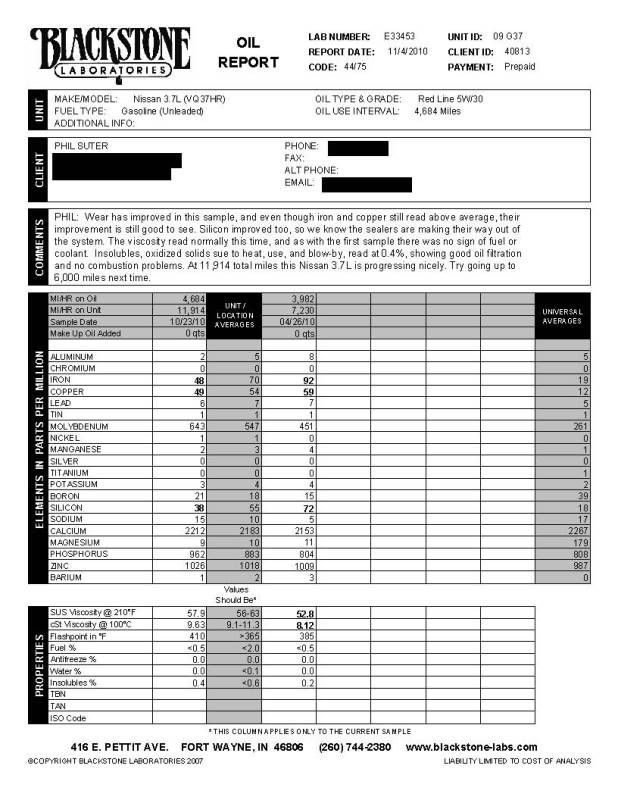

Heres my comparison of Nissan Ester oil UOA and Redline UOA. Note the Moly, calcium, phosphorous, boron, sodium, barium, potassium, magnesium, and zinc specs are very similar and if I covered up the viscosity and flashpoints, it would be hard to tell them apart based on their additive packages.

Last edited by philter25; 12-13-2010 at 04:56 PM.

#12

Registered User

iTrader: (4)

Per what I posted in another thread but I dont want to retype:

And theres a reason Redline and Amsoil both arent API certified. To meet API certification they would need to change the additive package and it would reduce the protection from both oils. Both companies believe that the API's phosphorus limit is too low. (Phosphorus = ZDDP)

If they wanted to be API certified, they could easily just reduce the amount of phosphorous in their oil. Some oil fanatics would argue that the API specs actually limit the use of some high performance better oils which would provide better protection for their engine...... which would be pretty beneficial to our engine, which is one that produces a lot of heat.

On the other hand, if you compare the VOA's of Schaeffers and Redline and Amsoil, depending on what VOA you look at, theres only a 100 ppm difference.

Also, Nissan Ester Oil is API certified. But after running it and UOA data, theres no way in hell I'd put that in my car for an OCI. Numerous UOA's have shown the same exact thing. Just because its API certified, doesnt mean its the best for this car.<!-- google_ad_section_end -->

More info on the whole API certified vs non-api certified:

AMSOIL and API Licensing Certification & Warranty

Amsoil and Redline and a few others are in the same boat. Its a good read.

Some interesting tidbits from AMSOIL's website:

Quote:

<TABLE cellSpacing=0 cellPadding=6 width="100%" border=0 itxtvisited="1"><TBODY itxtvisited="1"><TR itxtvisited="1"><TD class=alt2 style="BORDER-RIGHT: 1px inset; BORDER-TOP: 1px inset; BORDER-LEFT: 1px inset; BORDER-BOTTOM: 1px inset" itxtvisited="1">Why are some AMSOIL Synthetic Motor Oils API licensed and some are not?

There are two primary reasons:

1. There are strict phosphorus additive level restrictions placed on API certified oils that would

minimize the full performance and extended oil drain capability of AMSOIL motor oils.

2. The API does NOT allow read-across approvals for synthetic motor oils, and therefore

certification costs become unrealistic.</SPAN>

Phosphorus Restrictions

Full API licensing, or certification, would impose strict phosphorous limitations on AMSOIL motor oils. This limitation is the main reason most AMSOIL motor oils are not API licensed. AMSOIL INC. currently disagrees with this limitation and feels strongly that the reduced wear and longer oil and additive life achieved through higher levels of properly formulated and balanced phosphorous content is more important than the arbitrary API phosphorous limit that does not give any consideration to the NOACK volatility level of an oil. When chemistry is developed that will provide superior engine wear protection with reduced phosphorous levels, or NOACK volatility considerations are put in place, then the phosphorous level will become a non-issue.

Keep in mind that every time a person changes their motor oil, they are introducing a fresh quantity of phosphorus from the new oil to the engine’s catalytic converter. By the very nature of providing extended oil drains, in a typical application AMSOIL motor oils actually introduce a smaller volume of phosphorus to the catalytic converter over the life of the vehicle, which means it is more friendly to the catalytic converter and is actually a more environmentally friendly product to use.

Read-Across Approvals

In the lubricants industry petroleum motor oils that are API licensed have “ read-across approval .” What this means is you can seek API licensing approval on a specific product, with a particular additive package, and then use read-across approval to market this same oil formulation in any number of oil viscosities. For example, if you license a 5W-30 with additive package ABC, then you can market your 10w-30 or 10W-40 engine oils with the API certification donut provided these other viscosities use additive package ABC. The API does NOT allow read-across approval on synthetic engine oils, which means that every single oil viscosity must be individually/separately, certified to carry the API certified donut mark of the API.

API Licensing, via read across approval, works for petroleum products, but the licensing process has a “stranglehold” on synthetic technology. This puts AMSOIL INC. in a tough situation. If we followed conventional practice, not only would we find it necessary to buy “ off the shelf ” oil formula components from specific vendors - and be at the mercy of their pricing - we would not be able to make any major improvements to the lubricant formulas for 2 to 3 years, without new testing and, not surprisingly, even higher associated costs.

The cost for running a test program for a single passenger car motor oil formulation is from $125,000 to $300,000, depending on if the formula passes the tests the first time through, or if it requires multiple test runs or formula modifications to achieve a passing average.

Note: That amount goes to $275,000 to $500,000 for a Heavy Duty Diesel licensing program on a specific formula.

Once that testing is complete and the formula has passed all of the minimum requirements, it can be licensed for $825 per year for non-members and $625 per year for members. There is also a small royalty fee per gallon sold for all gallons over one million. The length of time between new specifications is now approximately 2 to 3 years, which does not allow a great deal of time to recover testing costs. To solve this problem, the API should establish base stock interchange guidelines for synthetic basestocks - just as they have for other basestocks - as well as develop interchange guidelines for other components so that manufacturer’s and marketers of synthetic engine oils have an even playing field as it relates to API certification costs. </TD></TR></TBODY></TABLE>

Nissan Ester Oil VOA's put their phosphorous at around 400+ ppm depending on samples. Redline is 800+ ppm. So you can put Nissan Ester Oil in your car every 3750 miles, because it shears at 4000 miles, and over the course of 7500 miles, you would have put 800 ppm of Phosphorous in your car. OR you can put in Amsoil or Redline and do a longer OCI. Both have better protection for your engine, and over the same 7500 miles, you would only put in 800 ppm of Phosphorous.

This is scientific data which can be found through any VOA or even UOA's all over the boards, my350z, and BITOG.

Case in point is look at the UOAs of Redline and Amsoil and Royal Purple. They all make non-API certified oils that are much much much much much better for your car than cheaper oils which are API certified.

And as stated in your owners manual, Infiniti even recommends their Ester oil for their schedule 2 maintenance (which is 7500 miles) that is API certified but numerous UOA's show it shearing and breaking down at 4000 miles.

You are more likely to see engine problems from following infiniti's advice and using their Nissan Ester oil on schedule 2 than you are from using Redline or Amsoil on schedule 2.

Also, Im guessing that the reason they state in the manual is to use only API certified oils is incase some idiot puts somethig stupid like Crisco in his car and wonders why he has engine failure.

The reason its not API certified is because of the Phosphorous, and because excessive amounts of oil burned with Phosphorous can damage your cat converters. It really has nothing to do with engine wear or lubrication. Phosphorous is important for valve train protection in your engine, and as most of us know, the VVEL is pretty complicated and produces a lot of heat and needs the protection. And the reason the API cert cut the phosphorous ppm requirement was that the government pushed for a 150,000 mile cat converter lifetime. The quickest way to do that was to drop the phosphorous spec in the API. So the only thing the dealer could void your warranty on would be cat failure..... and if your engine is burning that much oil that your cats are failing before your warranty is up, then you have a serious problem!<!--

OEM's are now mandated to warranty the emission system and the way to ensure that is to require an API rated oil with lower ZDDP content. OEM's are essentially trading the engine lifespan against the emission lifespan. It should be noted again that premature cat failure due to ZDDP would only be caused if your engine was burning oil. If you engine is properly sealed and maintained and doesnt burn oil, then running the higher concentration of ZDDP isnt a concern. However, the only way OEM's can adhere to the government mandate is through by recommending an API SM rated oil with .08% of ZDDP.

As a side note, I believe some old cars have seen engine failure (flat tappet camshafts) due to using newer oils which are API certified because the new API cert oils have the lower concentration of phosphorus. I believe the current level is under 600 ppm, or .08%.

Now, on the other side, the GOOD part of the API ratings is that it forms MINIMUMS for cheaper oils to have to adhere to. So when you put that cheap dealer API rated dino oil in your car, you know it at a minimum meets API spec.

Last edited by philter25; 12-13-2010 at 05:23 PM.

#13

Registered User

The law says the onus is on the manufacturer to prove that the oil caused the failure.

Thread

Thread Starter

Forum

Replies

Last Post

Junchao Sun

Engine, Drivetrain & Forced-Induction

25

10-01-2015 12:41 PM

FlyIce

G37 Sedan

7

09-29-2015 04:07 AM